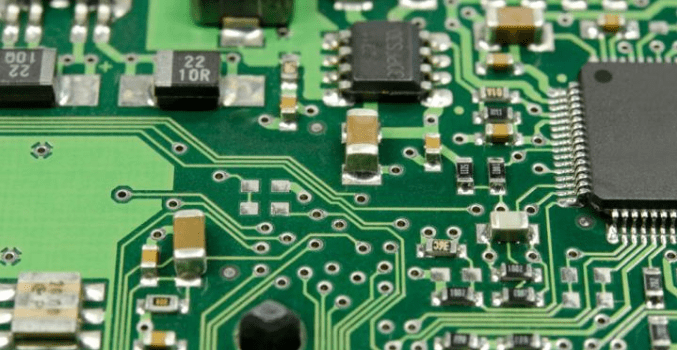

PCB

The kind of PCB that needs to be used in industry depends on the specific application and requirements. Industrial PCBs are used in a wide range of applications, including manufacturing, energy, transportation, and more. These PCBs must be designed and manufactured to be durable, reliable, and able to withstand harsh industrial environments. They must also be able to operate at high temperatures, be resistant to vibration and shock, and have a high level of thermal conductivity.

What is an industrial control PCB

An industrial control PCB is a type of PCB used in industrial control systems to control and monitor the operation of industrial equipment and machinery. These PCBs are designed to operate in harsh industrial environments and are used in a wide range of applications, including manufacturing, energy, transportation, and more.

Industrial control PCBs are used to control and monitor industrial processes, such as temperature control, motion control, and data acquisition. These PCBs may contain sensors, actuators, microcontrollers, and other electronic components to enable effective control and monitoring of industrial equipment.

Features of industrial control board

The features of an industrial control board can vary depending on the specific application and requirements. However, some common features of industrial control boards include:

- Durability: Industrial control boards must be able to withstand harsh industrial environments and be resistant to factors such as temperature, humidity, and vibration. These boards may be subject to high levels of wear and tear, so they must be designed and manufactured to be long-lasting.

- Reliability: Industrial control boards must be highly reliable to ensure that they can operate continuously and effectively in industrial applications. Any failure of an industrial control board can lead to costly downtime or safety hazards, so it is crucial that these boards are designed and manufactured to be dependable.

- Customizability: Industrial control boards must be designed and manufactured to meet the specific requirements of the application and may need to be customized to accommodate different types of sensors, actuators, and other components. They must be flexible enough to work with a wide range of equipment and processes.

- Safety: Industrial control boards must be designed and manufactured to meet safety standards and regulations to ensure that they do not pose a risk to workers or the environment. They must be able to operate safely in hazardous environments and be designed with fail-safes to prevent equipment damage or accidents.

- Connectivity: Industrial control boards may need to be able to communicate with other devices and systems, such as sensors, actuators, and control software, to enable effective control and monitoring of industrial equipment. They must be designed to work with a wide range of communication protocols and interfaces to enable seamless integration with other equipment and systems.

Overall, industrial control PCB must be designed and manufactured to meet the specific requirements of the industrial application and to ensure reliable, safe, and effective operation of industrial equipment and machinery. These PCBs are critical components in industrial processes and play a key role in ensuring that industrial processes run smoothly and efficiently.